- Fırınlar için Muflar

- Yatay Fırınlar İçin Muflar

- Dikey Fırınlar İçin Muflar

- Çan Fırınları İçin Muflar

- Karbonlama Nitrürleme için Muflar

- Konveyör fırınları için muflar

- Amonyaklı Krakerler İçin Muffles

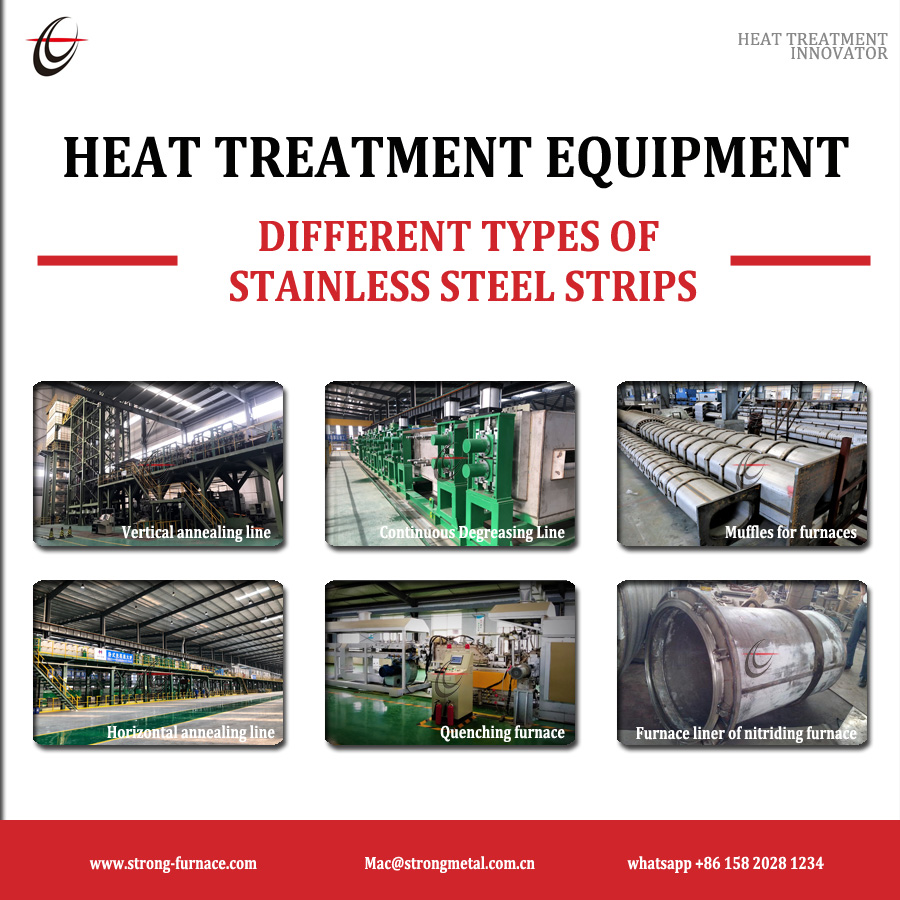

Çelik levhanın ısıl işlem ekipmanları nelerdir?

Mori for you to introduce the steel plate heat treatment equipment what?

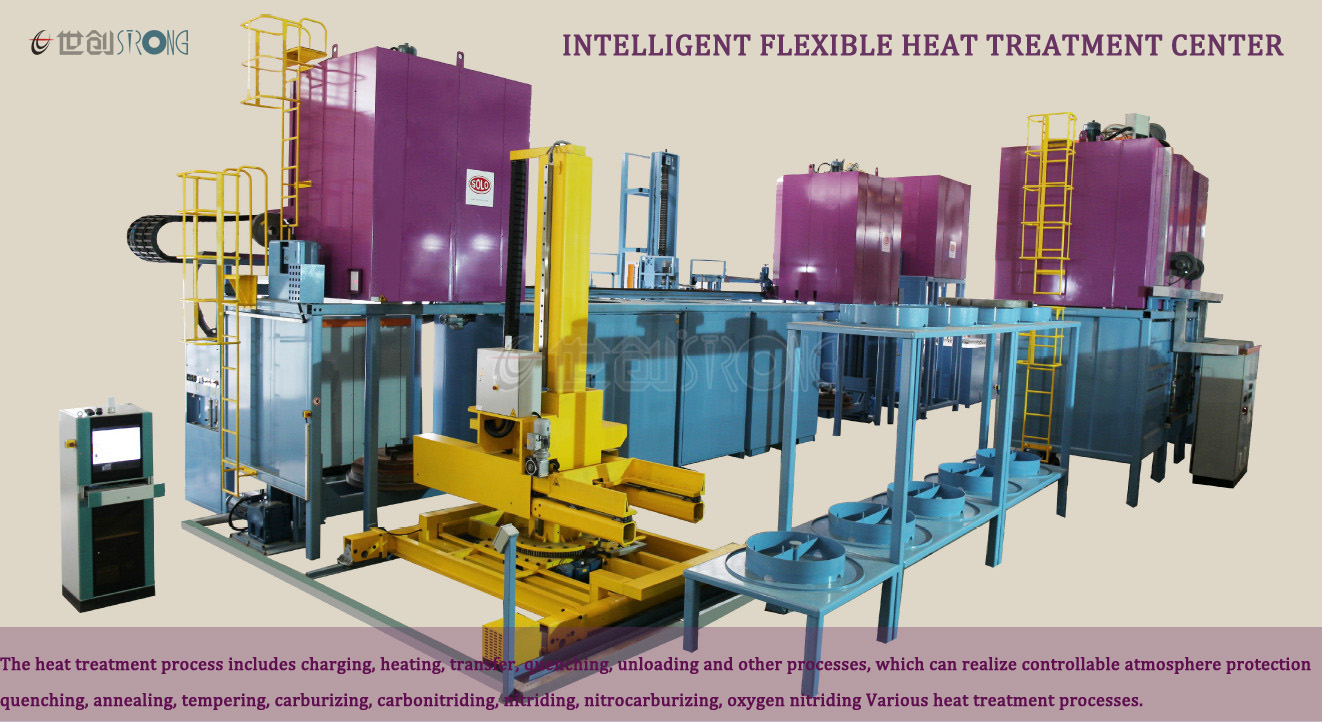

Heat treatment equipment for steel plates usually includes the following:

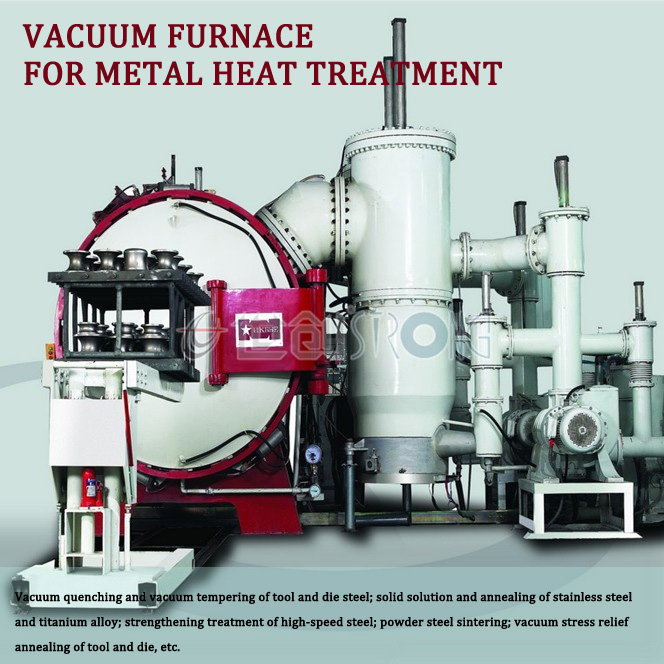

Furnace: The furnace is a device used to heat the steel plate to the required temperature. The types of furnaces include resistance furnaces, gas furnaces and electric arc furnaces.

Hardening device: hardening device is used for the rapid cooling of steel plates that have been heated to the appropriate temperature. Common hardening devices are water hardening, oil hardening and gas hardening.

Annealing furnace: An annealing furnace is a device that continuously heats steel plates at low temperatures to improve material properties. Typically, annealing furnaces heat the steel plate to a temperature range between 400 ° C and 800 ° C.

Passivation furnace: Passivation furnace is a kind of equipment that passivates steel plates at high temperatures. Passivation treatment can improve the corrosion resistance of steel plates.

Nitriding furnace: A nitriding furnace is a device that nitrides steel plates in a high temperature environment. Nitriding treatment can improve the hardness and wear resistance of steel plate.

Today's introduction - muffle furnace

The furnace is a container in the furnace that holds the fuel or melting material. The material of the furnace is generally high temperature and corrosion resistant metal, such as steel, cast iron, stainless steel and so on. The shape and size of the furnace furnace depends on the structure and use of the furnace.

The main functions of the furnace are:

Holding of fuel or smelting materials;

Conduction heat;

Prevent direct contact of fuel or smelting material with the furnace.

Furnace gall is an important part of the furnace, its quality and performance directly affect the service life and efficiency of the furnace.

Here are some common types of furnace benders:

Steel furnaces: Steel furnaces are the most widely used type of furnaces. The steel furnace has good strength, stiffness and toughness, and the price is relatively cheap.

Cast iron furnace gall: Cast iron furnace gall has good heat resistance and corrosion resistance, but the weight is larger and the manufacturing cost is higher.

Stainless steel furnace: Stainless steel furnace has good corrosion resistance and wear resistance, but the price is higher.

When using the furnace, the following matters should be noted:

The furnace should be inspected regularly and replaced in time if it is damaged.

Furnace bile should be kept clean to prevent ash and slag accumulation.

The furnace should be used correctly to avoid severe vibration or shock.

Through proper use and maintenance, the service life of the furnace can be extended.